A Comprehensive Guide to Folder Gluers for Cardboard Boxes

2024-09-07

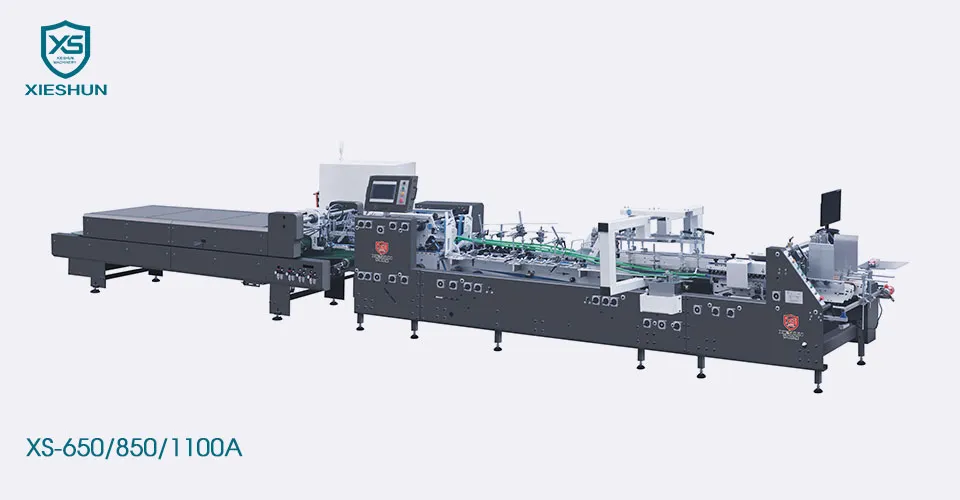

Folder gluers are a critical component in the packaging industry, especially for businesses that manufacture cardboard boxes. These machines play a pivotal role in automating the process of folding and gluing flat cardboard sheets into fully formed boxes. In this blog, we’ll explore the key features, benefits, and applications of folder gluers for cardboard boxes.

What is a Folder Gluer?

A folder gluer is a machine designed to fold flat cardboard blanks and apply adhesive to assemble them into boxes. It is typically used in industries where large-scale box production is required, such as food packaging, electronics, and consumer goods. The machine handles various types of cardboard, including corrugated and solid boards, making it versatile for a wide range of packaging needs.

Key Features of Folder Gluers

1. Precision Folding: Folder gluers ensure precise and consistent folds, minimizing errors and ensuring high-quality output. This is particularly important for industries requiring uniform packaging.

2. High-Speed Production: Most folder gluers are designed to handle high-volume production. Some advanced models can process thousands of boxes per hour, increasing efficiency and productivity.

3. Versatility: Folder gluers can accommodate a variety of box types, including straight-line boxes, crash-lock bottom boxes, and four-corner boxes. This makes them suitable for different packaging applications.

4. Adjustable Glue Application: These machines are equipped with glue applicators that precisely control the amount and type of adhesive applied. This ensures that the boxes are securely assembled and meet the necessary strength requirements.

5. Automated Operation: Modern folder gluers are highly automated, reducing the need for manual labor. They come with user-friendly interfaces that allow operators to adjust settings for different box sizes and designs.

Benefits of Using Folder Gluers for Cardboard Box Production

1. Increased Efficiency: Automation speeds up the production process, enabling businesses to meet high demand with minimal manual intervention.

2. Cost-Effective: By reducing the need for manual folding and gluing, folder gluers help lower labor costs while ensuring consistent quality.

3. Enhanced Box Quality: The precise folding and adhesive application ensure that boxes are well-constructed, durable, and capable of protecting their contents during shipping.

4. Customization: Folder gluers can be configured for various box sizes and shapes, making them ideal for businesses that require custom packaging solutions.

5. Environmentally Friendly: Many folder gluers support eco-friendly adhesives and materials, which align with sustainability initiatives in packaging.

Applications of Folder Gluers in Different Industries

Folder gluers are used across a variety of industries that rely on cardboard packaging:

- E-Commerce: With the rise of online shopping, the need for sturdy, customizable boxes has increased. Folder gluers help e-commerce businesses produce boxes quickly and efficiently.

- Food & Beverage: Companies in the food industry often use folder gluers to create packaging for items such as frozen foods, baked goods, and beverages.

- Retail & Consumer Goods: Retailers require a wide range of packaging solutions, from simple straight-line boxes to more complex designs. Folder gluers provide the flexibility needed to meet these demands.

- Pharmaceuticals: Packaging in the pharmaceutical industry must meet strict standards. Folder gluers ensure precise construction of packaging that protects delicate products during transportation.

Conclusion

Folder gluers for cardboard boxes are a cornerstone in modern packaging. They offer speed, precision, and flexibility, making them invaluable for businesses in various industries. Whether you're looking to enhance your production line's efficiency or ensure the highest quality of packaging, investing in a folder gluer can provide substantial benefits.