Understanding the Basics of Plastic Recycling Machines

2024-07-17

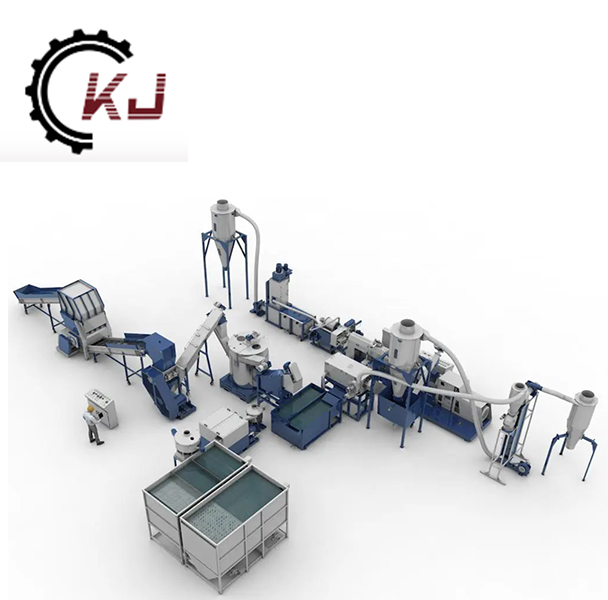

Plastic recycling has become an essential part of waste management and environmental conservation. With the increasing awareness about the detrimental effects of plastic pollution, the need for efficient recycling methods has grown exponentially. Central to this process are plastic recycling machines. But what exactly are these machines, and how do they work? Let's dive into the basics.

What is a Plastic Recycling Machine?

A plastic recycling machine is a specialized piece of equipment designed to process and recycle various types of plastic waste. These machines can handle a wide range of plastics, from common household items like bottles and packaging to industrial plastic waste. The primary goal is to transform plastic waste into reusable materials, thereby reducing the need for new plastic production and minimizing environmental impact.

How Does it Work?

The plastic recycling process involves several stages, each facilitated by different components of the recycling machine. Here’s a simplified breakdown:

1. Collection and Sorting: The first step is the collection of plastic waste, followed by sorting it into different categories based on the type of plastic. This step is crucial as different plastics require different processing methods.

2. Shredding: The sorted plastic is then fed into a shredder, which breaks it down into smaller pieces. This makes it easier to handle and process further.

3. Washing: The shredded plastic is washed to remove any contaminants such as dirt, labels, or adhesives. Clean plastic ensures higher quality recycled products.

4. Melting and Extrusion: The clean plastic pieces are melted down and extruded into new shapes, such as pellets or fibers. This step is often performed by an extruder, a key component of the recycling machine.

5. Pelletizing: In this stage, the extruded plastic is cut into small, uniform pellets. These pellets can be used as raw material for manufacturing new plastic products.

Types of Plastic Recycling Machines

There are various types of plastic recycling machines, each designed for specific recycling processes:

- Shredders: Used for breaking down large plastic items into smaller pieces.

- Granulators: Further reduce the size of plastic pieces for easier handling.

- Extruders: Melt and reshape plastic into new forms.

- Pelletizers: Convert melted plastic into uniform pellets.

Benefits of Using Plastic Recycling Machines

- Environmental Impact: Reduces plastic waste in landfills and oceans, contributing to a cleaner environment.

- Resource Conservation: Decreases the demand for new plastic production, conserving natural resources like oil.

- Economic Benefits: Creates opportunities for businesses in the recycling industry and reduces production costs for manufacturers using recycled materials.

Conclusion

Plastic recycling machines play a pivotal role in managing plastic waste and promoting sustainable practices. By understanding their functions and benefits, we can appreciate the importance of recycling and support efforts to reduce plastic pollution. Investing in advanced recycling technologies is not only beneficial for the environment but also crucial for building a sustainable future.